Why You Need Specialist Welding Inspection Racine for Your Projects

Wiki Article

Empowering Your Business With Customized Welding Examination Provider for Every Task

In the realm of company procedures, the relevance of welding evaluations tailored to details task needs can not be overemphasized. Personalized inspection intends not only offer as a crucial part of quality control however likewise play an essential role in guaranteeing the architectural integrity and safety of the end product. By delving right into the nuanced elements of welding assessment services, companies can open a realm of benefits that prolong past plain conformity. Whether it be small-scale jobs that demand precision or huge undertakings requiring streamlined effectiveness, the tailored method to welding assessments stands as a cornerstone for success.Significance of Tailored Welding Inspections

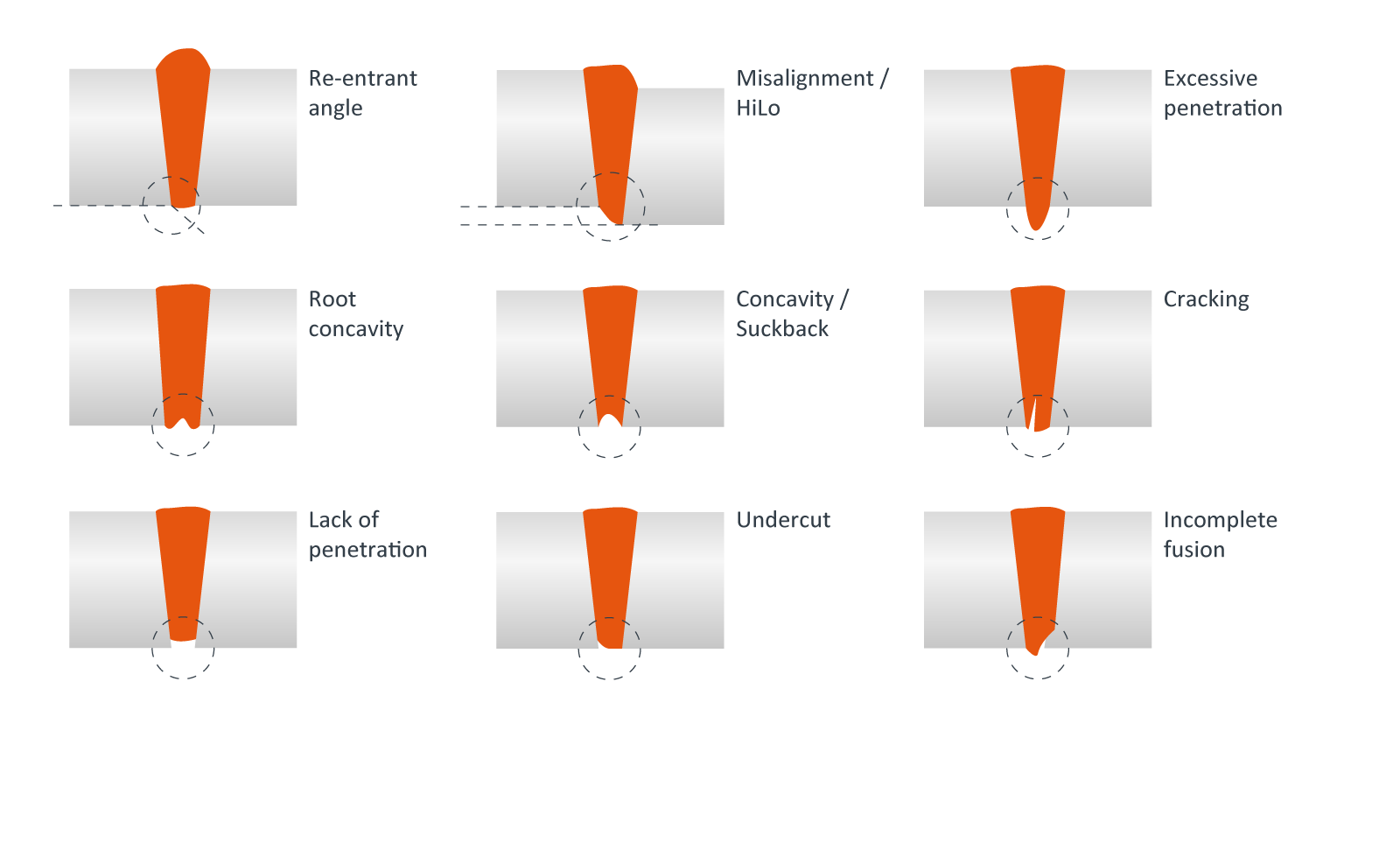

Customized welding evaluations play an important duty in guaranteeing the high quality and stability of welds in various markets. These specialized inspections are customized to fulfill the certain needs of each project, thinking about elements such as the kind of materials being bonded, the welding method made use of, and the market standards that need to be abided by. By tailoring the evaluation process, potential flaws and problems can be determined and dealt with at an early stage, protecting against expensive rework or failings down the line.Various markets have differing demands when it comes to welding high quality, and customized evaluations help companies fulfill these criteria effectively. Additionally, customized assessments help improve overall effectiveness and performance by improving the assessment procedure to focus on the most essential areas.

Advantages of Personalized Assessment Strategies

Customized assessment strategies provide businesses a calculated advantage by specifically lining up assessment procedures with the special needs of each welding project. By tailoring inspection strategies to fit the specific needs of a project, businesses can make certain that all important aspects are thoroughly examined, therefore minimizing the threat of welding issues and making certain conformity with market standards.

Customized assessment strategies provide businesses a calculated advantage by specifically lining up assessment procedures with the special needs of each welding project. By tailoring inspection strategies to fit the specific needs of a project, businesses can make certain that all important aspects are thoroughly examined, therefore minimizing the threat of welding issues and making certain conformity with market standards.Moreover, tailored assessment strategies assist companies save expenses in the lengthy run by avoiding rework and lessening the possibility of project delays. By capturing prospective issues early with tailored examinations, services can address them immediately, staying clear of costly blunders down the line. Additionally, customized evaluation plans can enhance overall job high quality by offering an extra comprehensive and comprehensive analysis of welding procedures, products, and workmanship. This, subsequently, can bring about boosted customer contentment and a more powerful reputation for delivering top quality welding tasks.

Tailored Services for Small-Scale Projects

For small welding projects, specialized assessment solutions can be tailored to meet the details demands and constraints of the task scope - Welding Inspection Racine. While bigger jobs commonly have more standard assessment processes, small jobs call for an extra focused and customized strategy because of their unique attributesIn small projects, every weld is important, and even minor problems can have substantial effects. Customized welding inspection solutions for these jobs include a complete understanding of the task goals, materials made use of, welding techniques, and market regulations. By personalizing the inspection strategy to suit the range and complexity of the project, potential problems can be recognized early, bring about boosted weld quality and overall task success.

Additionally, customized solutions for small-scale jobs can aid maximize resources and decrease costs. By focusing evaluation efforts on areas that matter most for the particular project, unneeded inspections can be prevented, saving both time and money. This targeted approach guarantees that the evaluation procedure is effective, reliable, and ultimately adds to the effective conclusion of small-scale welding projects.

Additionally, customized solutions for small-scale jobs can aid maximize resources and decrease costs. By focusing evaluation efforts on areas that matter most for the particular project, unneeded inspections can be prevented, saving both time and money. This targeted approach guarantees that the evaluation procedure is effective, reliable, and ultimately adds to the effective conclusion of small-scale welding projects.Enhancing Performance in Huge Tasks

In the realm of massive welding projects, the focus moves towards enhancing evaluation processes to improve overall effectiveness and task success. Utilizing sophisticated assessment strategies, such as automated welding examination systems and real-time tracking devices, can considerably minimize assessment times while improving precision.Furthermore, establishing clear interaction channels and procedures in between evaluation teams, job managers, and welders is vital for making certain that examinations are performed without delay and that any kind of problems are quickly dealt with. Carrying out an organized strategy to assessment scheduling, focusing on important welds, and designating resources efficiently can help prevent traffic jams and keep the task on track. Constant training and upskilling of examination personnel additionally play a vital duty in improving performance in big jobs, making certain that inspectors are furnished with the current expertise and strategies to execute their responsibilities successfully.

Ensuring Compliance and Organization Defense

Preserving strict adherence to welding laws and sector standards is extremely important for securing service passions and redirected here making certain functional conformity. By focusing on conformity, companies can reduce dangers, stay clear of look at this web-site pricey fines, and maintain their track record within the sector. Welding examination services play an important duty in making sure that all welding processes fulfill the required codes and criteria, offering companies with the guarantee that their projects are executed in a certified and risk-free fashion.Furthermore, compliance with welding laws is not practically fulfilling legal needs; it is likewise about making certain the security of employees, the general public, and the setting. Non-compliance can cause mishaps, structural failures, and environmental dangers, all of which can have serious repercussions for a business's profits and online reputation. By spending in tailored welding assessment services, services can proactively address and identify compliance problems before they intensify, consequently protecting their interests and cultivating a society of security and quality within the company.

Conclusion

In conclusion, customized welding examination services play a vital role in encouraging services by making certain high quality, compliance, and efficiency in projects of all sizes. Customized evaluation strategies assist companies fulfill sector standards, protect their track record, and minimize risks. Whether it's a massive venture or a small-scale task, tailored solutions can enhance quality control and general success. Buying customized welding inspections is a strategic choice for services seeking to accomplish quality in their welding processes.

Additionally, tailored inspections help boost general efficiency and efficiency by improving the examination procedure to concentrate on the most critical areas.Custom-made evaluation strategies offer organizations a tactical advantage by specifically aligning evaluation processes with the one-of-a-kind requirements of each welding job. By focusing inspection efforts on locations that matter most for the specific job, unnecessary assessments can be prevented, conserving both time and money. Utilizing advanced inspection methods, such as automated welding inspection systems and real-time monitoring tools, can considerably decrease evaluation times while enhancing accuracy.Furthermore, establishing clear interaction networks and protocols between evaluation groups, project managers, and welders is crucial for ensuring that assessments are conducted immediately and that any find more info kind of problems are promptly dealt with.

Report this wiki page